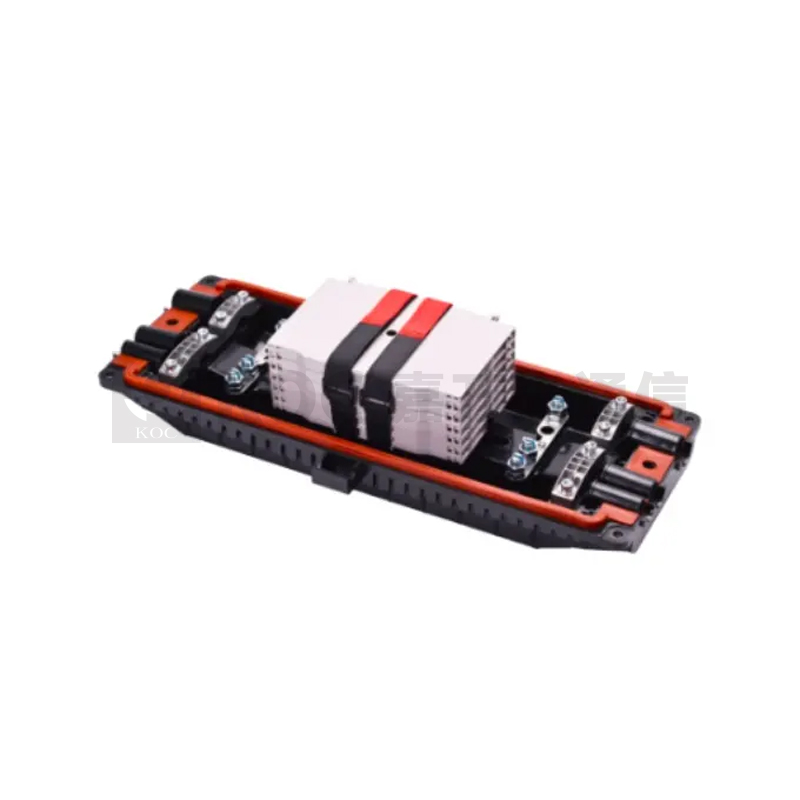

Scope of application

This Installation Manual suits for the Fiber Optic Splice Closure (Hereafter abbreviated as FOSC), as the guidance of proper installation.

The scope of application is: aerial, underground, pipeline, handhole. The ambient temperature ranges from -40℃ ~ 65℃.

Dimension and capacity

Outside dimension (LxWxH) | 450x220x160 (mm) |

Weight (excluding outside box) | 3100g - 3800g |

Number of inlet/outlet ports | 3 (pieces) on each side (total 6 pieces) |

Diameter of fiber cable | Φ7 - Φ23 (mm) |

Capacity of FOSC | Bunchy: 12 - 192 (Cores) / Ribbon: max. 432(Cores) |

Main components

Name of components | Quantity | Usage | Remarks |

Housing | 1 set | Protecting fiber cable splices in whole | Internal diameter: 378x136 (mm) |

Insert plate | 2 pairs | Fixing the housing | 175x56x30(mm) |

Fiber optic splice tray (FOST) | Max 8 pieces(bunchy) or 6pcs(ribbon) | Fixing heat shrinkable protective sleeve and holding fibers | Suitable for: Bunchy: 12,24(cores) Ribbon: 6 (pieces) |

Foundation | 1 set | Fixing reinforced core of fiber cable and fiber optic splice tray (FOST) |

|

Seal fitting | 1 set | Sealing between FOSC cover and FOSC bottom |

|

Port plug | 6 pieces | Sealing empty ports |

|

Pressure testing valve | 1 set | After injecting air it is used for pressure testing and sealing testing | Configuration as per requirement |

Earthing deriving device | 1 set | Deriving metallic components of fiber cable in the FOSC for earthing connection | Configuration as per requirement |

Main accessories and special tools

Name of accessories | Quantity | Usage | Remarks |

Heat shrinkable protective sleeve |

| Protecting fiber splices | Configuration as per capacity |

Nylon tie |

| Fixing fiber with protective coat | Configuration as per capacity |

Insulation tape | 1 roll | Enlarging diameter of fiber cable for easy fixing |

|

Seal tape | 1 roll | Enlarging diameter of fiber cable which fits in with seal fitting | Configuration as per specification |

Hanging hook | 1 set | For aerial use |

|

Earthing wire | 1 piece | Putting through between earthing device |

|

Abrasive cloth | 1 piece | Scratching fiber cable |

|

Labeling paper | 1 piece | Labeling fiber |

|

Special Wrench | 3 pieces | Fixing bolts and tightening nut of reinforced core |

|

Measuring paper | 1 piece | To measure circle, of which its diameter is enlarged with seal tape |

|

Buffer tube | To be decided by customers | Hitched to fibers and fixed with FOST, managing buffer | Configuration as per requirement |

Desiccant | 1 bag | Put into FOSC before sealing for desiccating air. |

|

Supplementary materials (to be provided by operator)

Name of materials | Usage |

Scotch tape | Labeling, temporarily fixing |

Ethyl alcohol | Cleaning |

Gauze | Cleaning |

Special tools (to be provided by operator)

Name of tools | Usage |

Fiber cutter | Cutting off fibers |

Fiber stripper | Strip off protective coat of fiber cable |

Combo tools | Assembling FOSC |

Universal tools (to be provided by operator)

Name of tools | Usage and specification |

Band tape | Measuring fiber cable |

Pipe cutter | Cutting fiber cable |

Electrical cutter | Take off protective coat of fiber cable |

Combination pliers | Cutting off reinforced core |

Screwdriver | Crossing / Paralleling screwdriver |

| Waterproof cover | Waterproof, dustproof |

Metal Wrench | Tightening nut of reinforced core |

Splicing and testing instruments (to be provided by operator)

Name of instruments | Usage and specification |

Fusion Splicing Machine | Fiber splicing |

OTDR | Splicing testing |

Provisional splicing tools | Provisional testing |

Notice: The above-mentioned tools and testing instruments should be provided by the operators themselves.